The pollution and carbon footprint from the laundry process has been increasingly scrutinized over the last few years, and rightfully so. While most launderers don’t think about it on a daily basis, the process of washing and drying textiles is incredibly energy intensive and can have a huge environmental impact. The good news is that there are ways to reduce this impact, and one of the best is by implementing a heat recovery system into laundries.

Heat recovery is a process which captures the heat from used laundry water and recycles it to heat up the incoming fresh cold water. This process helps to reduce the energy needed to heat cold water while also reducing water waste. Not only does this result in lower energy costs, but it also cuts down on emissions and reduces water consumption, making it an important part of any commitment to sustainability.

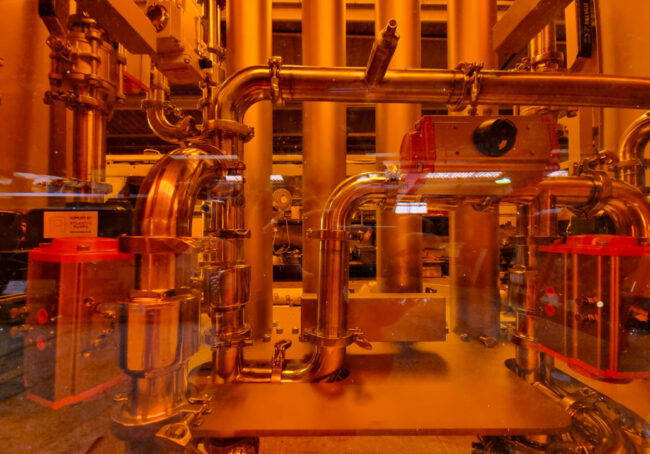

Heat recovery systems are easy to install and maintain, as well as efficient and cost effective. These systems don’t require any special maintenance, and since the technology has been around for many years, there is a full range of units to choose from to cater for any laundry size and type.

For any business that’s looking to reduce their energy costs and emissions, heat recovery is a great option. Not only does it reduce energy consumption and lower costs, but it can also make a significant contribution to the environment. Installing one of these systems in your laundry is a great way to aid and help build a sustainable future.